Assets Management

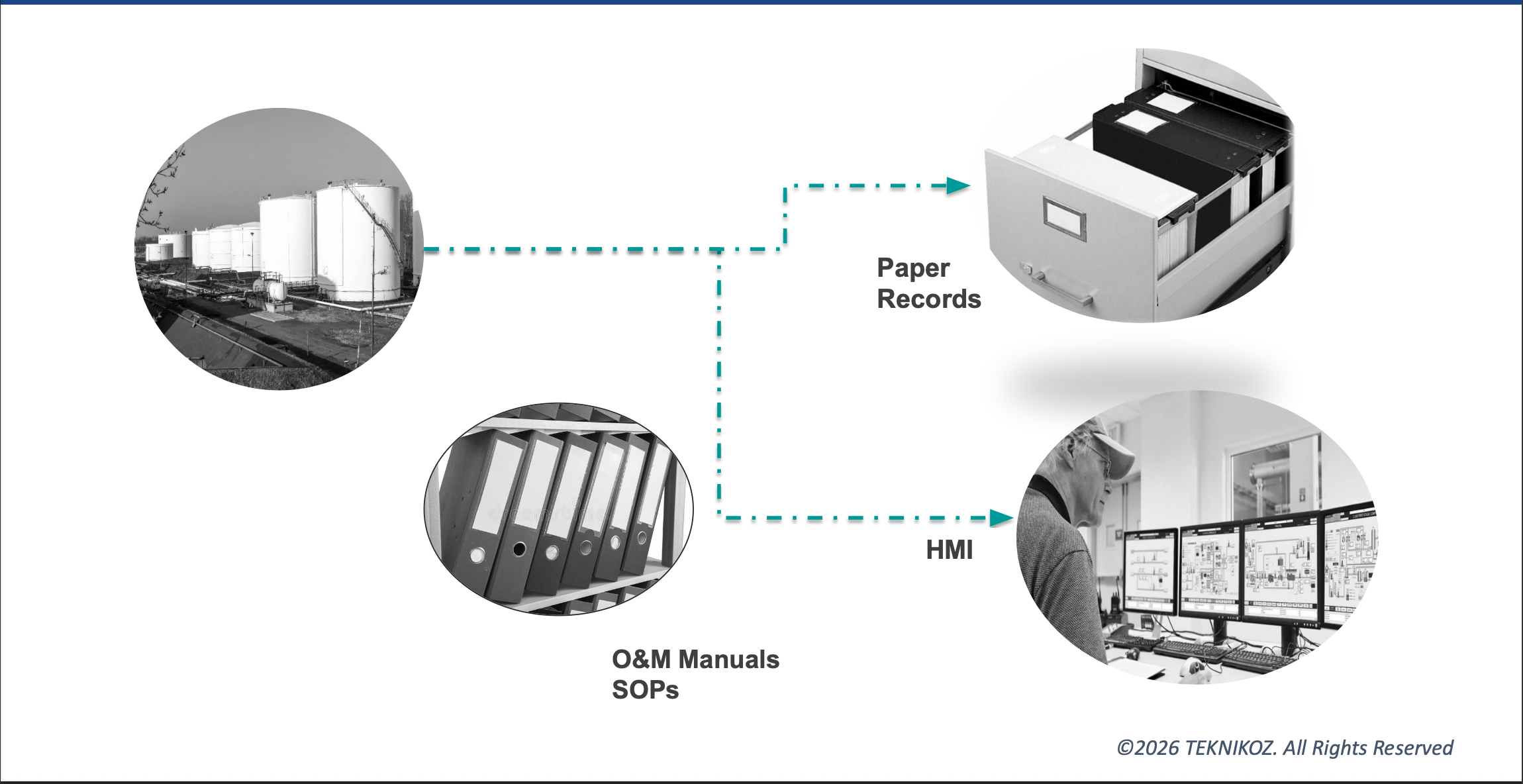

What Does A Traditional Asset Integrity Management Program Look Like?

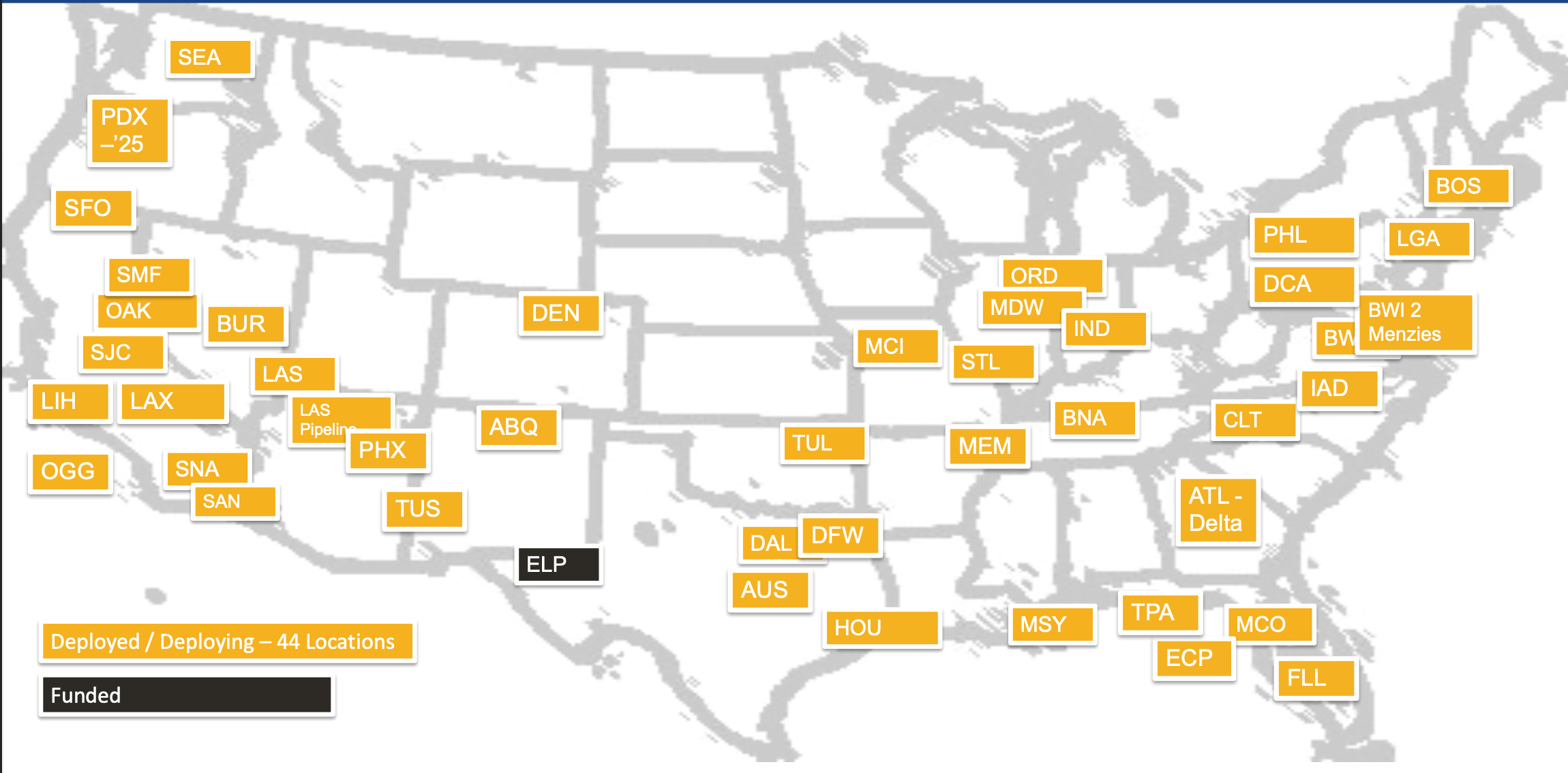

What All Airports Have We Enabled?

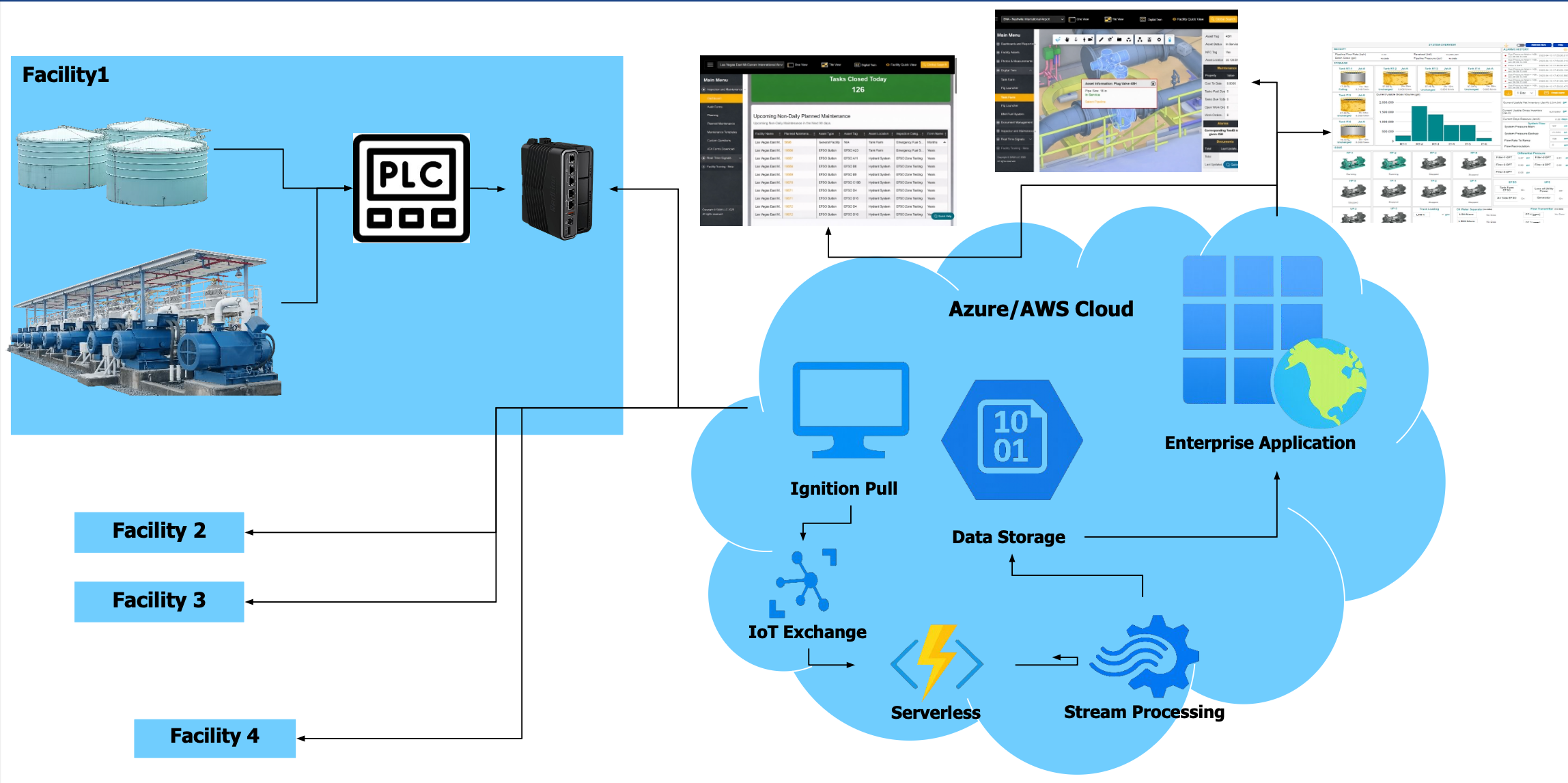

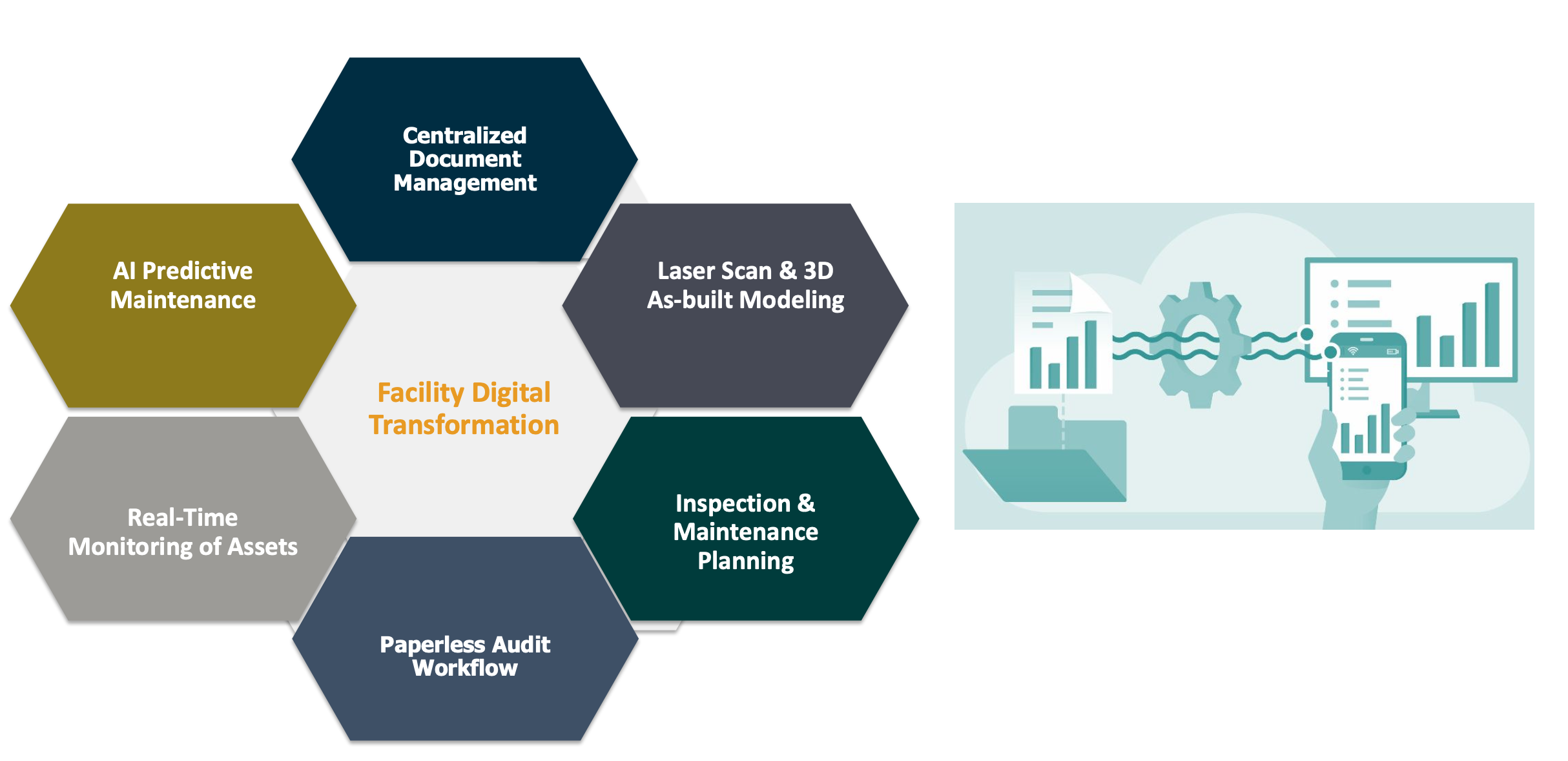

Solution Design – Fuel Facility

Solution Design – ENOC TANK FARMS

Subsidiaries

| Location | Type | Capacity (CBM) | Tanks |

|---|---|---|---|

| Dubai, UAE | Chemical | 54,401 | 53 |

| Dubai, UAE | Petroleum | 141,500 | 7 |

| Fujairah, UAE | Petroleum | 463,000 | 23 |

| Singapore | Petroleum | 1,252,184 | 59 |

Associates and Joint Ventures

| Location | Type | Capacity (CBM) | Tanks |

|---|---|---|---|

| Dubai, UAE | Petroleum | 936,755 | 55 |

| Fujairah, UAE | Petroleum | 2,608,540 | 73 |

| Saudi Arabia | Petroleum, Chemical | 288,100 | 26 |

| Morocco | Petroleum, Gas | 532,900 | 19 |

| Djibouti | Petroleum, Gas | 399,304 | 31 |

Horizon Singapore Terminals Private Limited (HSPTL) and UAE

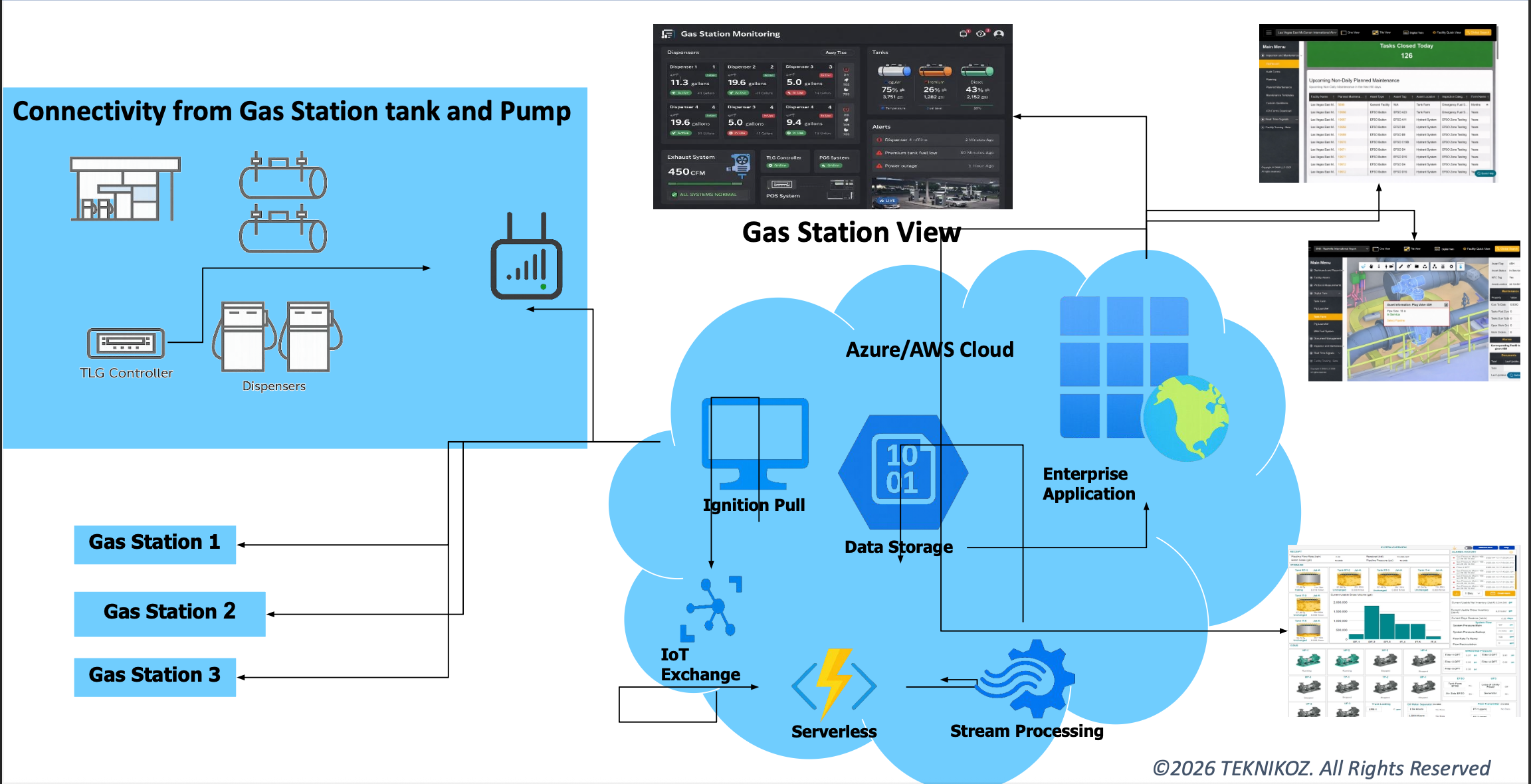

Solution Design – Gas Station

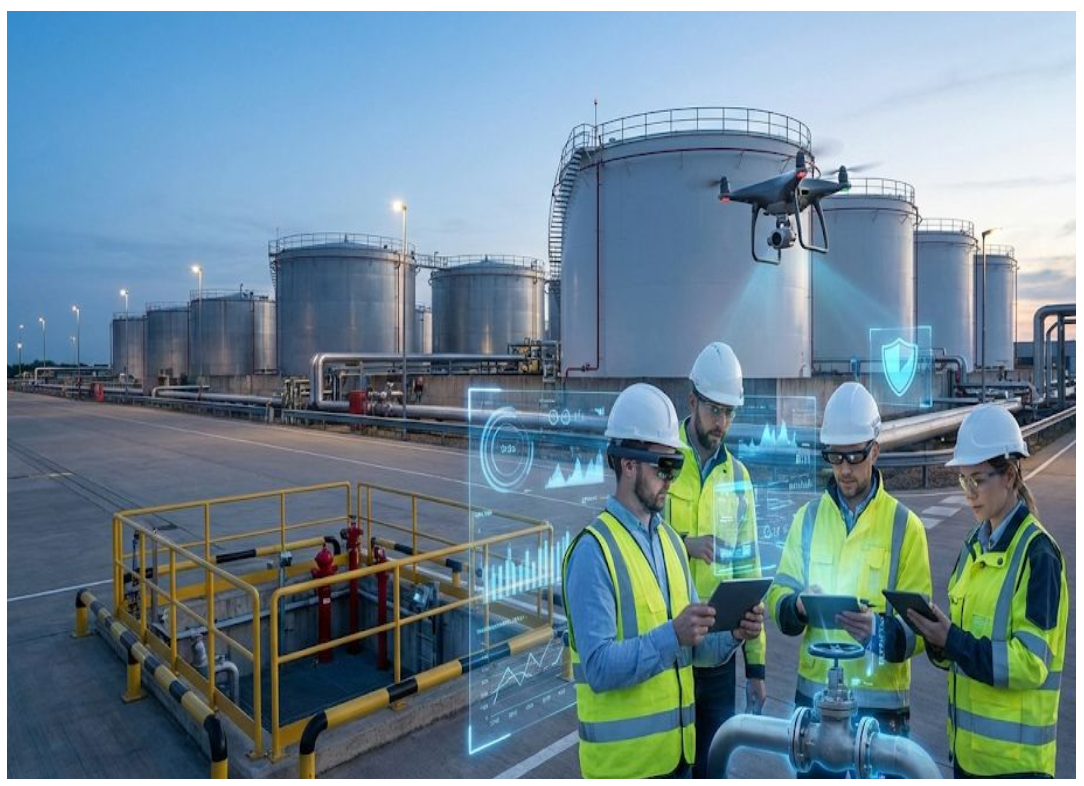

Why Take A Different Approach

WHY Trust our Solution with your fuel farm assets and hydrant systems?

Setting the industry standard for maintenance operations

Driving efficiencies

Monitoring the progress

Ensuring the highest levels of asset integrity across your fuel assets

Taking a Different Approach

Knowledge transfer between generations / team members

Being considerate of new ways of thinking/learning

Recognizing the challenges of operating this complex infrastructure

Improving communication across stakeholders

Taking advantage of all the information that's available to us

Creating systems to measure asset health and performance

Your fueling facility, centralized and digitized

As-Builts

▶ Photos & Measurements

- ▶

High resolution images across the facility.

- ▶

Conduct measurements using the scan data behind the images.

- ▶

Access to a virtual site walk, wherever you have internet.

▶ Digital Twin

- ▶

Reverse engineered 3D models available to design teams.

- ▶

Reduce project ramp-up time.

- ▶

Data repository for intelligent assets.

- ▶

Single source of truth for all users.

See As-Builts For Yourself

▶ Digital Twin

- ▶

Data repository for fueling assets built into the 3D model.

- ▶

Single source of truth for all users.

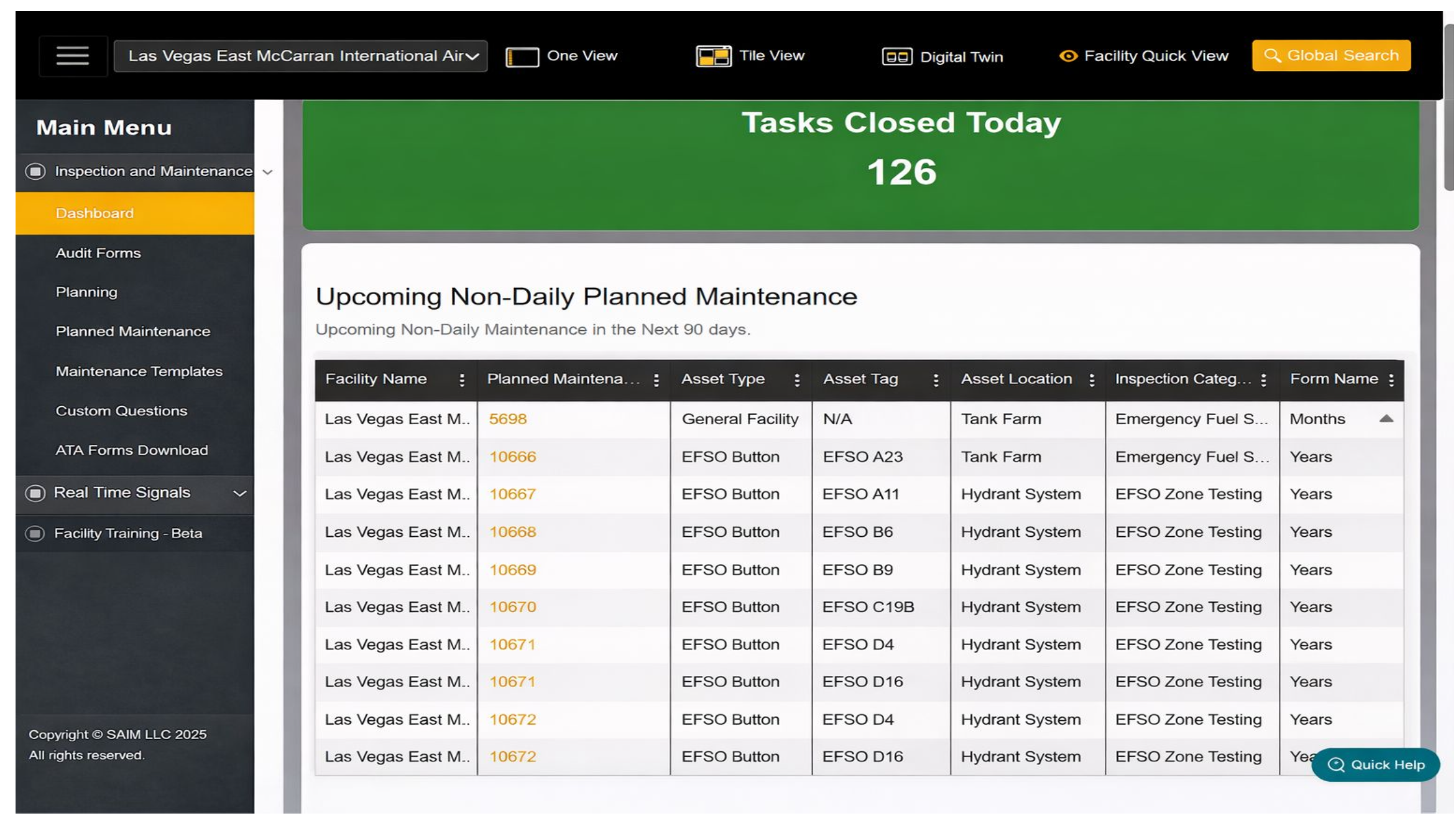

Maintenance Built for Operators

Inspection & Maintenance

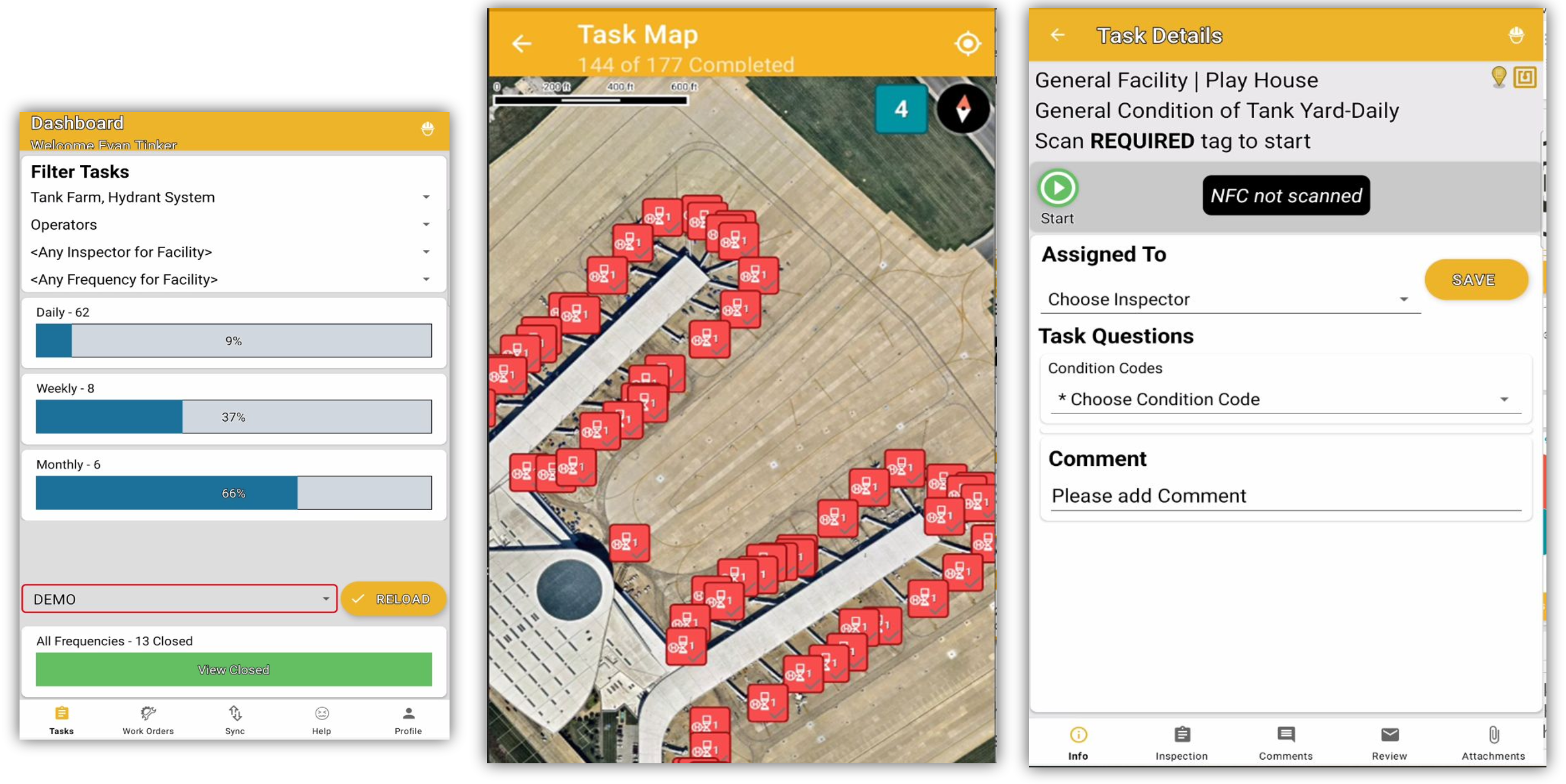

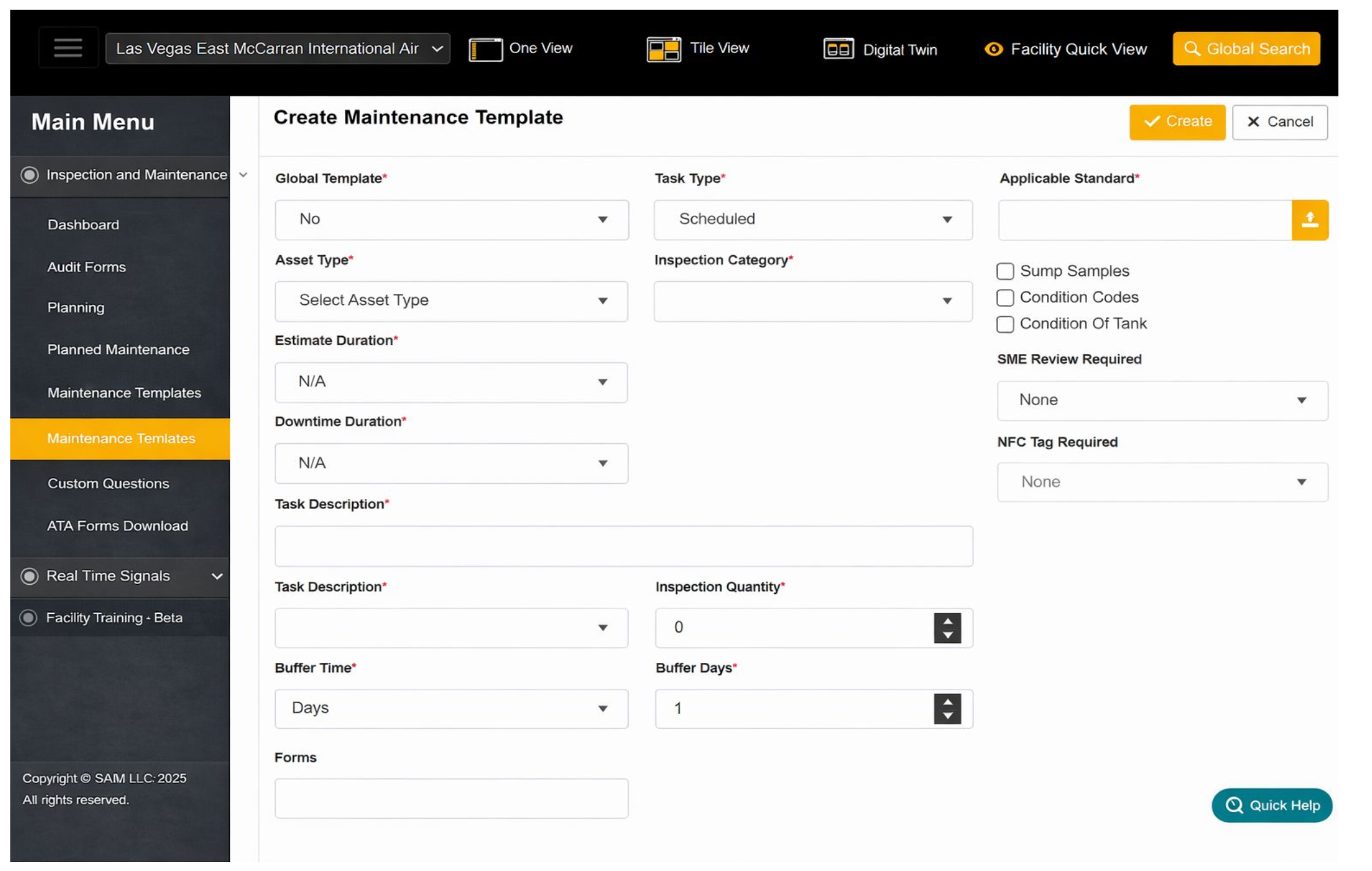

Schedule Recurring and Single Use Tasks for Daily Operations

Fuel Quality, Maintenance, Compliance, etc.

Automated Audit Forms

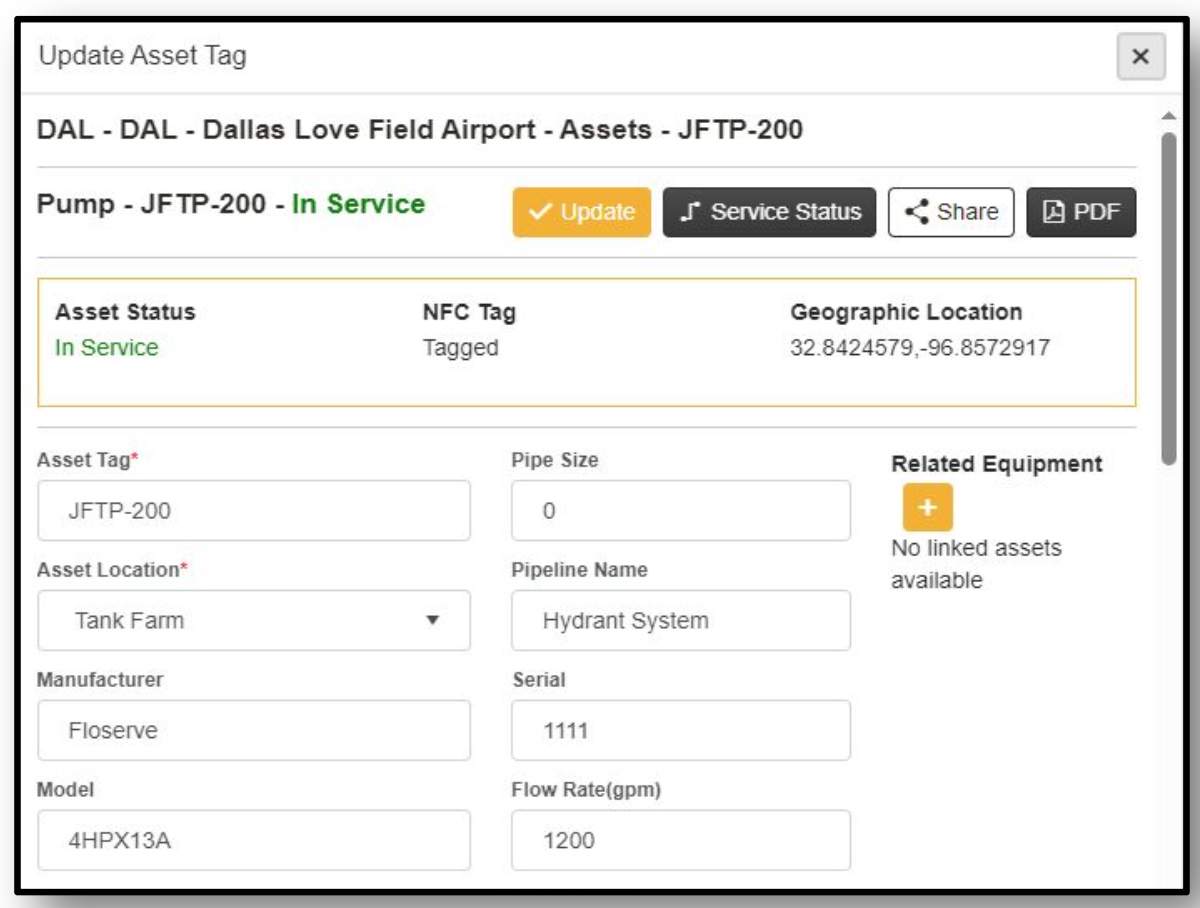

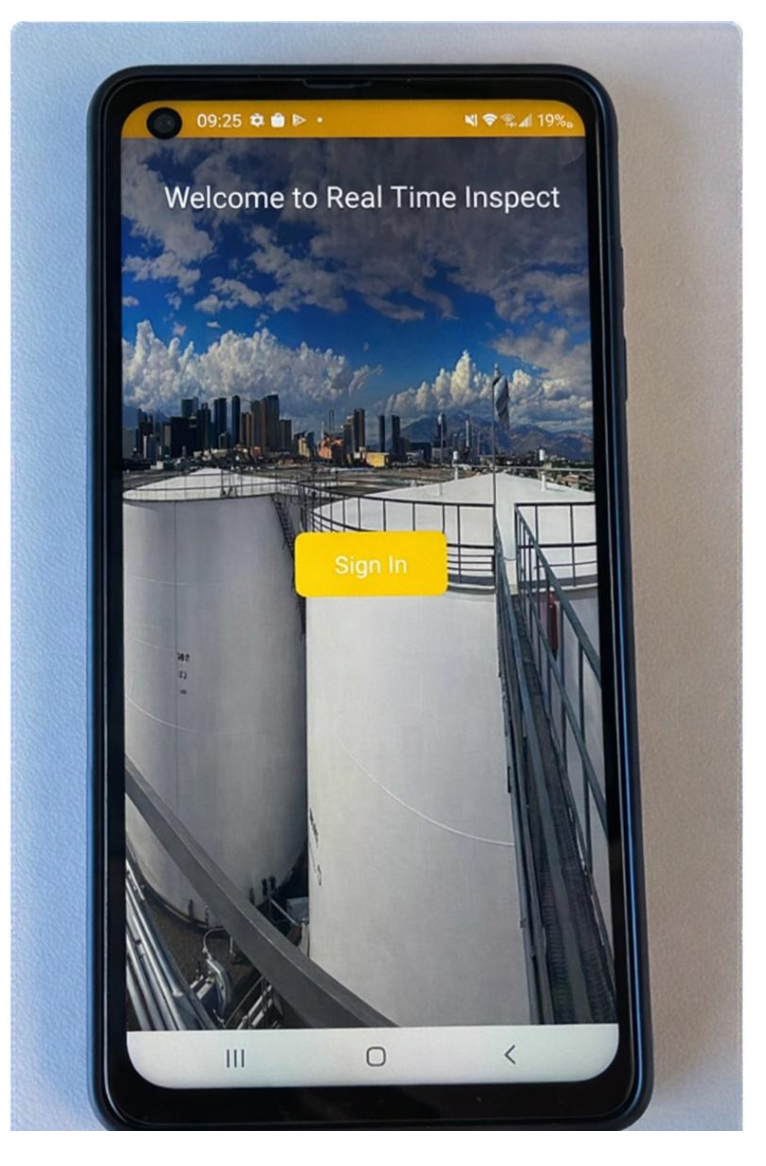

Real Time Inspect

Conduct Regular Maintenance Tasks

Submit and Complete Work Orders

Daily Tasks with Real Time Inspect

- ▶

NFC Tags (Near Field Communication) placed on major equipment and pits.

- ▶

Intrinsically-Safe handheld devices.

- ▶

All connected to your digital ATA paperwork.

Task Management Dashboard

Task Creation

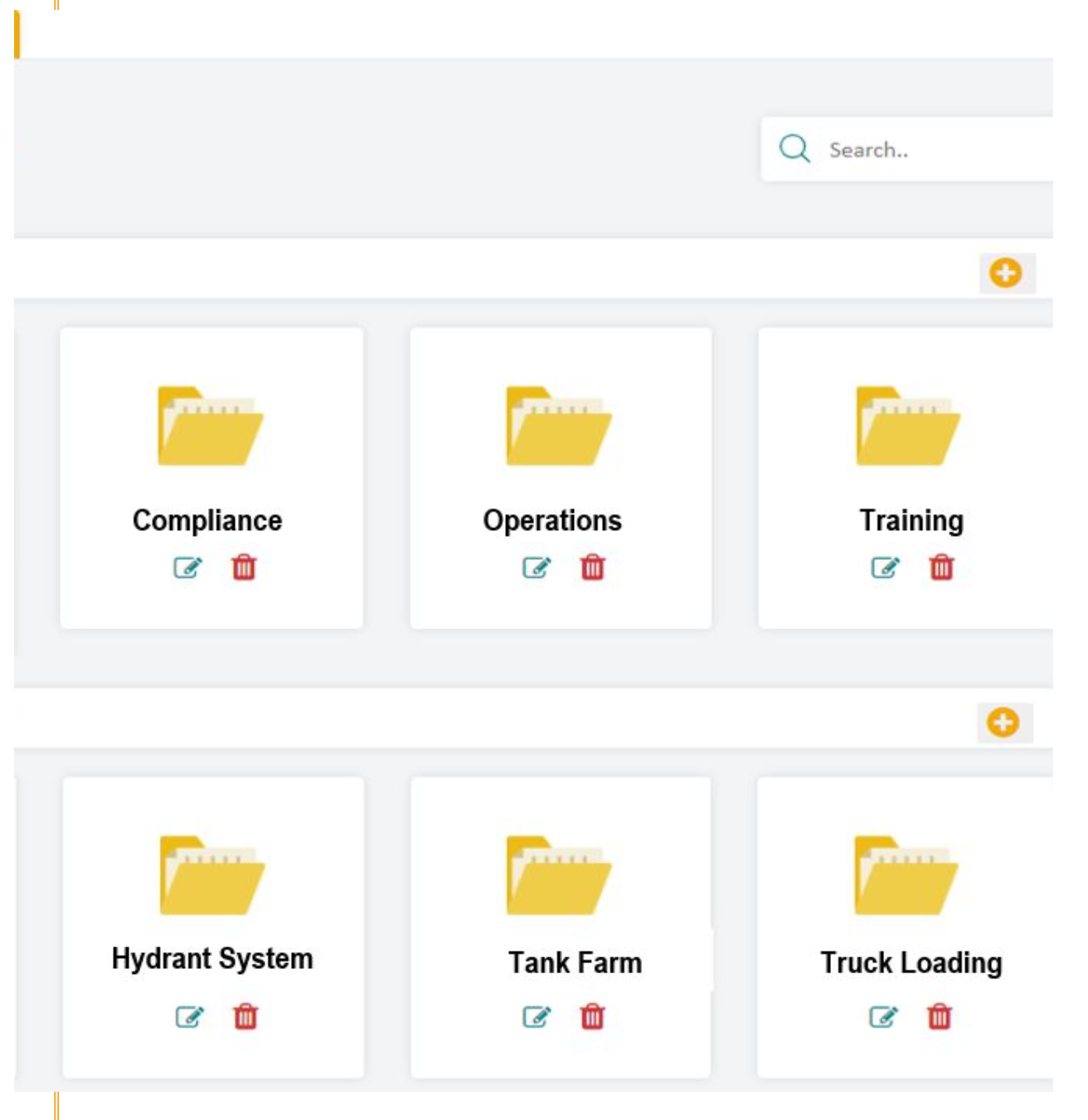

Document Management

▶ Document Management provides centralized online access for all facility documents.

Such as...

- ▶

Facility Design Drawings

- ▶

Engineering Reports

- ▶

Facility Lease Agreements

- ▶

Property Surveys

- ▶

Compliance Records

- ▶

Vendor Information

- ▶

Training Documents

- ▶

O&M Manual

- ▶

Tutorials

- ▶

Standard Operating Procedures

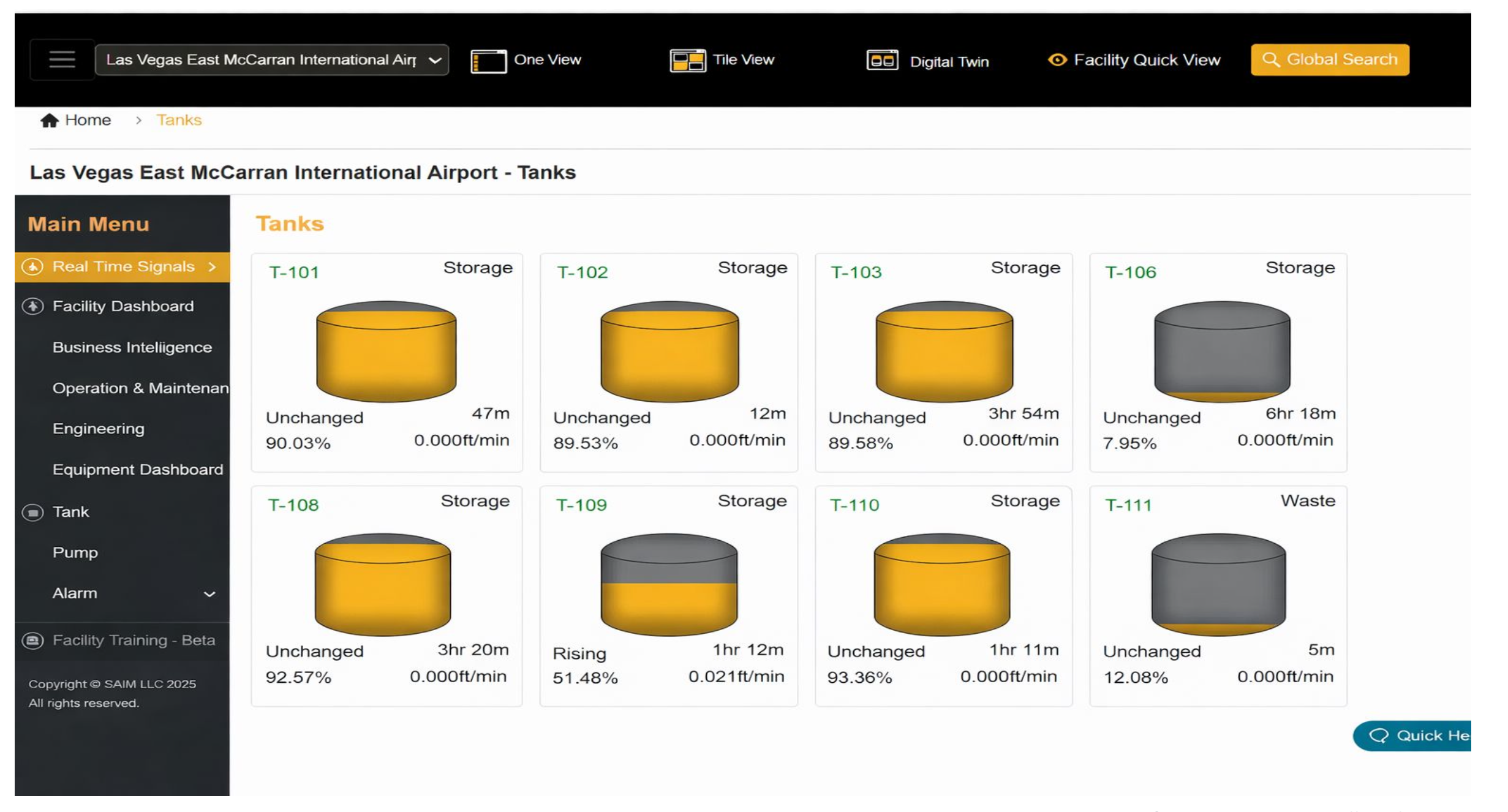

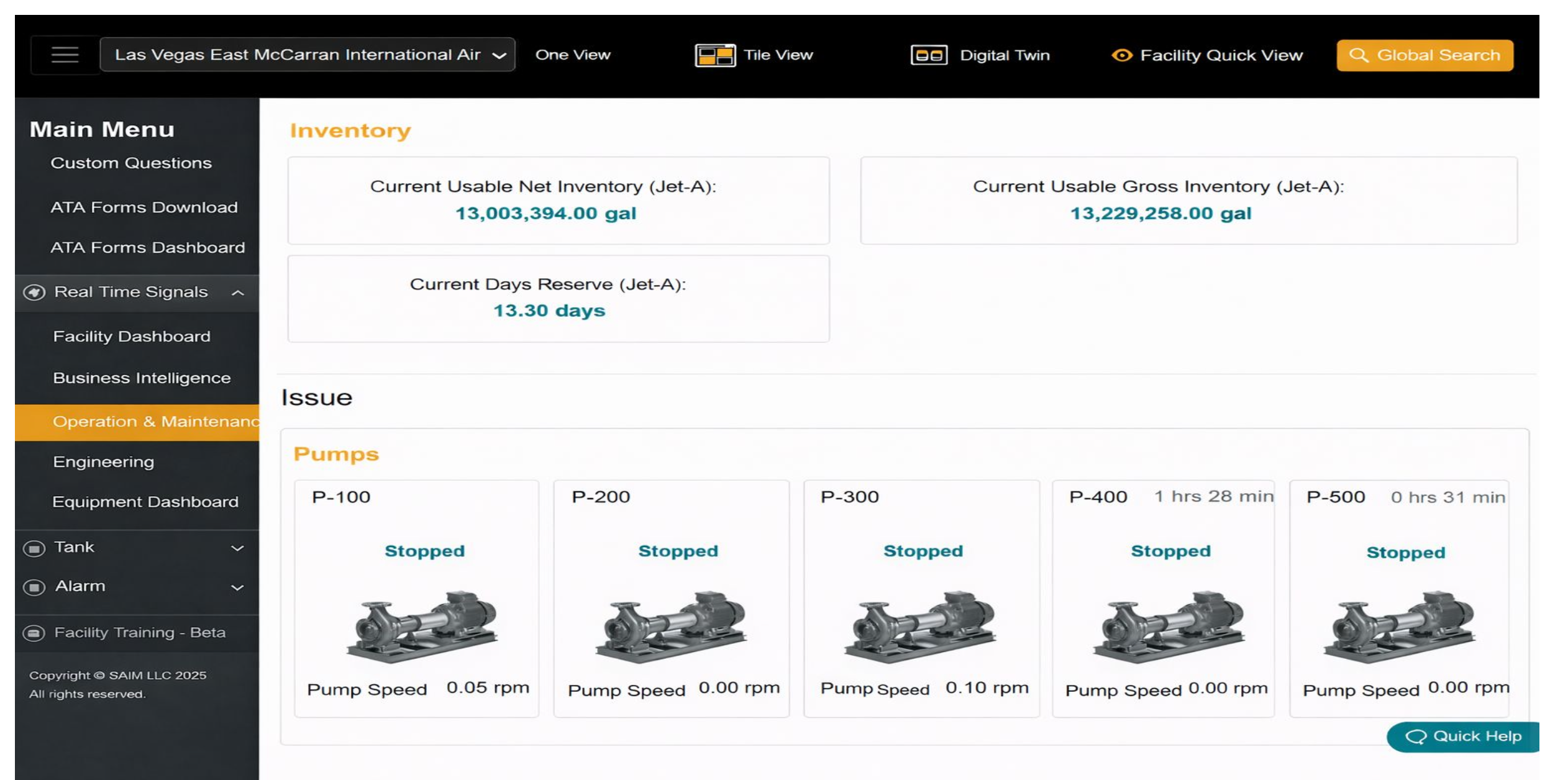

▶ Real Time Signals

▶ Viewable online from anywhere:

- •

Any facility signals coming to the PLC.

- •

Dashboards displaying real-time data.

- •

Data graphing and trending.

- •

Customizable user-defined threshold alarms.

▶ Provide access to stakeholders or design teams for data review to prevent failures.

▶ Get a head start on preventative maintenance.

Monitoring - Tank Assets

Monitoring - Pumps Asset

Key Customer References